What Do CCS and System 4000 Actually Do?

Monday, July 3, 2023

(0 Comments)

Posted by: Alex Rudie

By: Jay Broom, Marketing Specialist, and Kelly Harris, Global Director of Training, Lake Country Manufacturing, Inc.

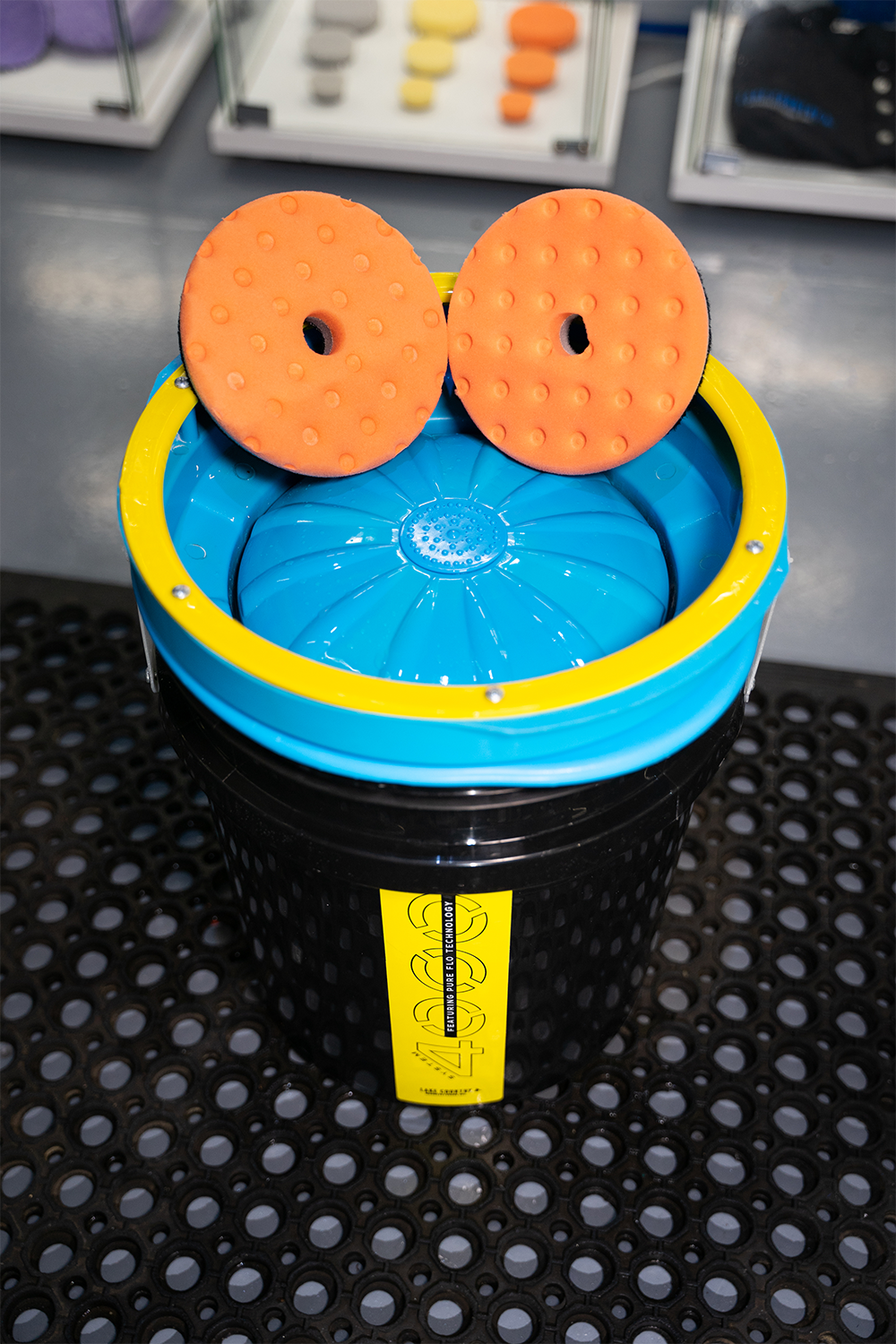

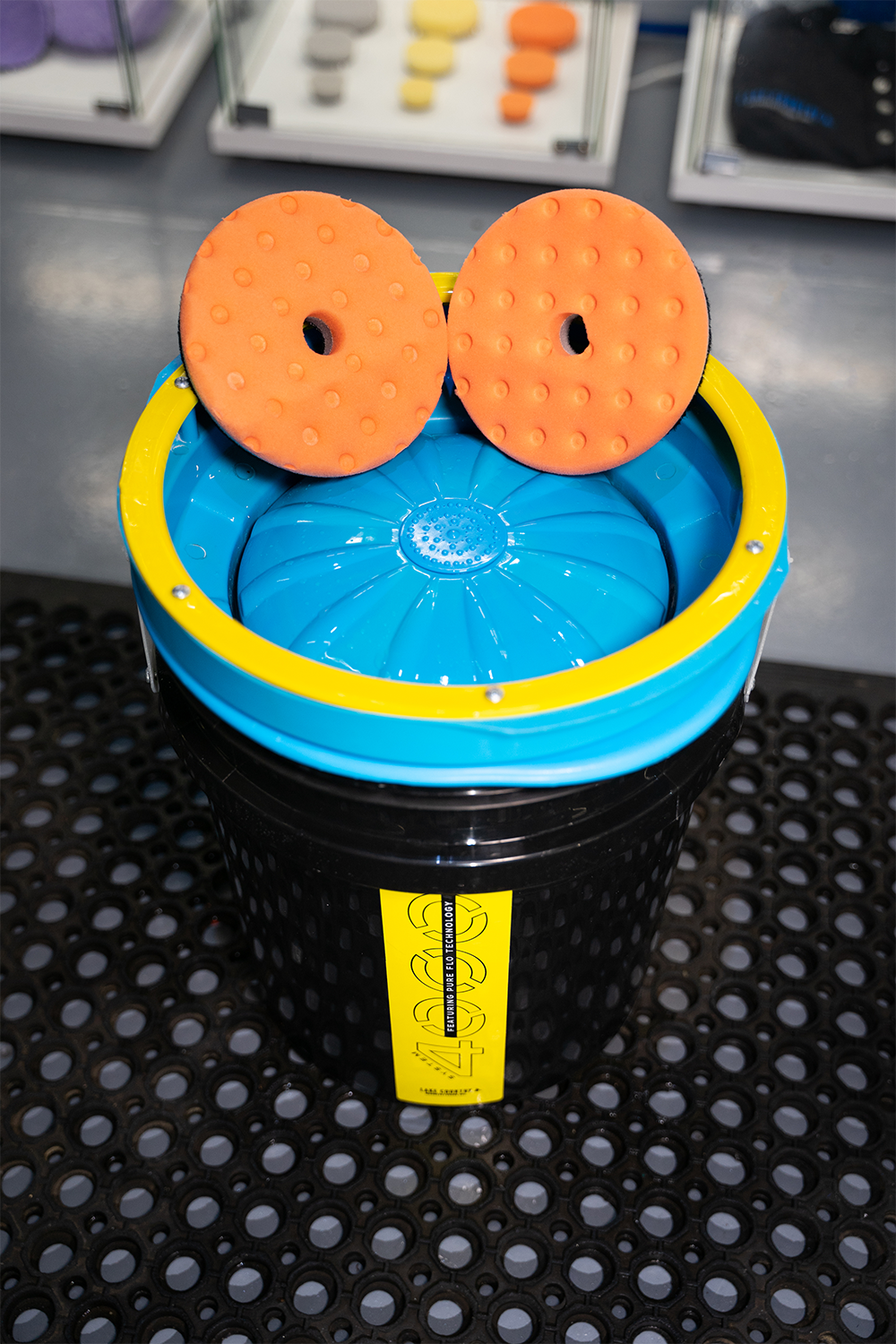

What Are Lake Country’s CCS Pads All About?As innovators in buffing and polishing pad technology, we introduced the CCS system on our pads several years ago. However, CCS has proved such an effective and useful feature that we recently included it as an option on our most modern pad designs (HDO and SDO). What is CCS Technology?Most typical foam pads are constructed from a porous open-cell material. Whether they are coarse and firm or smooth and plush, open-cell foams, always allow some of your compound or polish to soak beneath the surface. This is a natural part of the process, but we recognize there could be efficiency gains from keeping more of that abrasive media in action for longer. CCS (Collapsed Cell Structure) technology is an even distribution of dimples imprinted into the pad face. By ‘collapsing’ the cells inside those dimples, we close them off, creating reservoirs that prevent the compound from soaking away. But there’s more! - Even product distribution: Ensure that your liquid is evenly spread before and during every pass, so that the whole pad performs optimally. CCS gives a visual guide for priming!

- Longer/larger passes: As they diminish, most compounds lose a large amount of their cut. By effectively storing new compound in reserve on the pad face, CCS allows detailers to ‘refresh’ their cut and increase the size and duration of their pass by simply squeezing the pad — potentially saving time through a smoother workflow.

- Reduced temperatures: CCS dimples act as air pockets, keeping temperatures lower than an equivalent flat pad would. CCS pads feel smoother, more cushioned, and less ‘grabby’ than flat-faced counterparts.

- Increased durability: With CCS the foam, liquid, and paintwork interact slightly differently. Your compound will have a longer ‘aggressive’ lifespan meaning the pad doesn’t endure so much stress, offsetting the slight reduction in cut from the reduction in overall surface area.

Maintaining Your PadsIt’s not fun spending hours scrubbing pads in a sink; jet-washing could be a recipe for damaged construction (or flying pads); compressed air doesn’t remove oils, and eventually, washing machines are likely to deform your pads’ shape, appearance, and performance. System 4000 solves all these problems, but since its release, we’ve had many questions about how to get the best out of it.

How to Use System 4000- Do use Snappy Clean Boost — Use just enough to make a few bubbles and leave the wash water feeling a little slick. This breaks down compound oils.

- Don’t oversaturate the pad to begin with — Think of your pad like a pizza and give the middle of each slice just one good pump of cleaning solution. This ensures even distribution and prevents excess flooding/mess.

- Increase the speed gradually — Start slowly so that when the pad is wettest, you’re not slinging liquid all over your shop, car, or clothes. Once the bulk of the solution has been washed out, you can increase the speed significantly.

- Use the whole wash plate — The ribs massage the pad during cleaning, while the bumps in the center scrub clogged compound away (and help to separate microfiber strands). Pay attention to how your pad is rotating, and ensure each zone of the pad’s face gets treated by both parts of the wash plate.

- Check the wastewater from the pad — When you think the pad is clean, check the liquid coming out of it for clarity. This will tell you if it’s ready to dry off or needs another round.

- Dry the pad thoroughly — To minimize excess sling, lift the pad slightly (less than 1/2”, or about 1 cm) above the wash plate and select a low machine speed, building up gradually to full speed as you see the water being spun beneath the yellow lip. Be patient. It won’t be long before the pad is dry enough to use again. If you can press it firmly against your shirt without transferring moisture, you’re good to go.

- Plan your operation — Yes, you can use the same pad repeatedly, but it’s more efficient to have a short stack of them and clean a few at a time before moving on to the next section.

Cleaning at the End of the DayWhen the job's done there’s no need to do anything differently. I gather all my pads and clean them with the System 4000, leaving them on a rack overnight so they are bone dry in the morning. System 4000 helps maintain the ‘fresh from the packet’ look, feel, and performance of your pads for so much longer, and that’s what makes it such a valuable investment! Until next time – happy polishing!

Jay @ Lake Country IG: /jaybroomdetailing FB: /jay.broom.detailing *This article was provided by Lake Country Manufacturing, Inc., an IDA Diamond Sponsor. It does not constitute an endorsement, guarantee, warranty, or recommendation by the IDA. The IDA makes no representation or warranties about any information contained herein.

|